Mastering omnichannel inventory management has become a strategic imperative for retail businesses aiming to deliver a seamless and consistent experience to their customers. Companies opt for integrated order processing in their inventory systems to achieve a 25% boost in productivity, optimize space usage by 20%, and enhance stock utilization efficiency by 30%. This holistic approach involves optimizing inventory across diverse channels, from physical stores to online platforms, ensuring that customers can access accurate product information, check availability, and make purchases effortlessly. The significance of omnichannel inventory management lies in its ability to provide real-time visibility into inventory levels, enabling retailers to prevent stockouts, reduce overstocks, and streamline order fulfillment processes.

By integrating data-driven and innovative strategies such as click-and-collect and ship-from-store, retailers can enhance customer satisfaction, improve operational efficiency, and foster customer loyalty. In this blog post, we will explore key strategies for mastering omnichannel inventory management, offering insights into how businesses can elevate their retail operations for optimal success in a rapidly evolving market.

What is omnichannel inventory management and why is it important for any retailer

Omnichannel inventory management is a comprehensive approach to overseeing and optimizing inventory across all the channels through which a retailer interacts with its customers. This approach includes physical stores, eCommerce platforms, mobile apps, social media, and other touchpoints where customers can purchase or engage with the brand. The goal is to provide a seamless and consistent experience for their customers, regardless of the channel chosen, ensuring that they manage the inventory effectively to meet demand and enhance operational efficiency.

The simplest form of inventory management is the systematic control and tracking of a company’s goods or products. This basic concept includes the procurement, storage, and distribution to ensure that the right products are available in the right quantities at the right time. Effective inventory management aims to balance meeting customer demand and minimizing the costs of holding excess stock.

Omnichannel inventory management process

The omnichannel inventory management process involves a series of interconnected steps that efficiently oversee and optimize inventory across all channels. Below is an expanded outline of the central stages in the omnichannel inventory management process, spanning from procurement to sales:

Demand forecasting and planning

Begin with a thorough analysis of historical sales data, market trends, and customer behaviors to forecast future demand accurately. Accurate demand forecasting informs inventory planning, ensuring that the right quantities of products are available to meet anticipated customer demand.

Procurement and sourcing

Based on demand forecasts, initiate the procurement process to acquire inventory. This step involves working with suppliers, negotiating terms, and managing relationships. Efficient procurement ensures a steady and timely supply of goods, helping to prevent stockouts and maintain optimal inventory levels.

Receiving and quality control

After receiving inventory, conduct quality control checks to ensure that products meet established standards. This step includes verifying quantities, inspecting for damages, and assessing product quality. Quality control is crucial to prevent the distribution of defective or subpar products and maintain customer satisfaction and brand reputation.

Inventory storage and organization

Strategically store and organize inventory within warehouses or distribution centers. Implement efficient shelving, labeling, and tracking systems for easy retrieval. Well-organized storage facilitates quick and accurate order fulfillment, reducing lead times and enhancing overall operational efficiency.

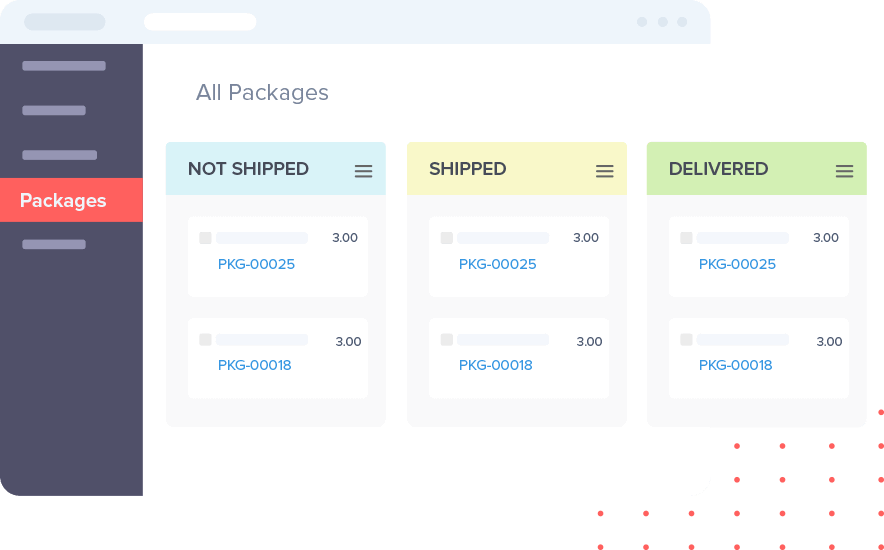

Real-time inventory visibility

Utilize technology, such as integrated inventory management systems, to maintain real-time visibility into inventory levels across all channels. This step includes both physical and digital inventory. Real-time visibility enables accurate decision-making, prevents overselling, and ensures that the customers have precise information about product availability.

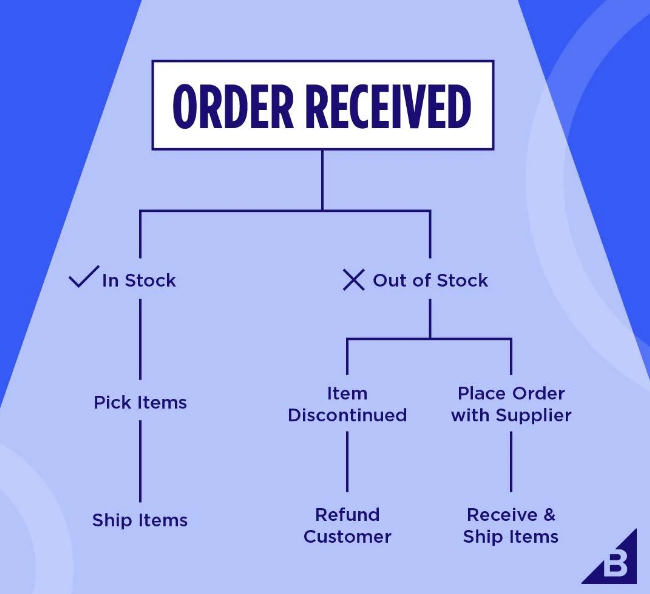

Order fulfillment strategies

Develop strategies for order fulfillment, considering options like ship-from-store, click-and-collect, or third-party fulfillment. Integrate inventory levels to fulfill orders from the most optimal locations. Optimizing order fulfillment strategies enhances customer satisfaction by providing flexible and efficient delivery options.

Returns management

Establish a streamlined process for managing product returns. This step includes assessing returned items for resale, restocking, or processing returns to suppliers. Effective returns management is essential for maintaining accurate inventory levels and ensuring that the returned items are handled appropriately.

Data analytics and performance metrics

Leverage data analytics to continuously monitor inventory performance, track key metrics, and assess the effectiveness of inventory management strategies. Data-driven insights enable continuous improvement, helping retailers adapt to changing market conditions and refine their inventory management processes.

Integration with sales channels

Integrate inventory management systems with various sales channels, including physical stores, eCommerce platforms, and mobile apps. This step will ensure synchronization and consistency. Integration prevents discrepancies in inventory information, allowing customers to access accurate and up-to-date product availability information across all channels.

Continuous optimization

Regularly review and optimize inventory management processes based on performance metrics, customer feedback, and market trends. This step may involve adjusting reorder points, refining demand forecasting models, or exploring new technologies. Continuous optimization is crucial for staying agile in a dynamic retail environment and maintaining competitiveness.

Key benefits of omnichannel inventory management

Omnichannel inventory management offers a range of benefits that contribute to the overall success of a retail business. Let’s elaborate on the key advantages:

Cost savings

Efficient omnichannel inventory management helps reduce costs associated with holding excess stock. By optimizing inventory levels and preventing overstock situations, businesses can minimize the expenses related to storage, insurance, and potential obsolescence. Cost savings extend beyond storage expenses; accurate demand forecasting and inventory planning also enable businesses to negotiate better terms with suppliers, take advantage of bulk purchasing discounts, and minimize the impact of stockouts on revenue.

Improved customer satisfaction

Omnichannel inventory management enhances the customer experience by providing accurate and real-time information about product availability across all channels. This characteristic helps prevent product unavailability, ensures timely order fulfillment, and offers customers flexibility in choosing how and where they receive their purchases. Customers today expect a seamless and consistent experience, whether they are shopping online, in-store, or through other channels. Omnichannel inventory management allows customers access to the products they want, reducing the likelihood of disappointment and contributing to increased satisfaction and loyalty.

Increased efficiency

Streamlining inventory processes and implementing omnichannel strategies improves operational efficiency. By integrating inventory systems with various sales channels, businesses can optimize order fulfillment, reduce lead times, and minimize the manual effort required for managing inventory across different platforms. The efficiency gains are not limited to order fulfillment but extend to other aspects of the supply chain, such as procurement, storage, and distribution. Real-time visibility into inventory levels facilitates quick decision-making and reduces the likelihood of errors in the order fulfillment process.

Optimized order fulfillment strategies

Omnichannel inventory management allows businesses to implement flexible order fulfillment strategies, such as ship-from-store, click-and-collect, or utilizing multiple distribution centers. This characteristic ensures that orders are fulfilled from optimal locations, reducing shipping costs and delivery times. Optimal order fulfillment strategies contribute to cost savings and enhance customer satisfaction. For example, ship-from-store leverages existing inventory in physical stores, reducing the need for separate fulfillment centers and improving overall supply chain efficiency.

Prevention of stockouts and overstock

Accurate demand forecasting and real-time inventory visibility help prevent both stockouts and overstocks. By understanding customer demand patterns and adjusting inventory levels accordingly, retailers can maintain a balance that meets customer needs without tying up excess capital in unnecessary stock. Stockouts can lead to lost sales and dissatisfied customers, while overstocks result in holding costs and potential markdowns. Omnichannel inventory management aligns inventory levels with actual demand, minimizing the financial impact of both scenarios.

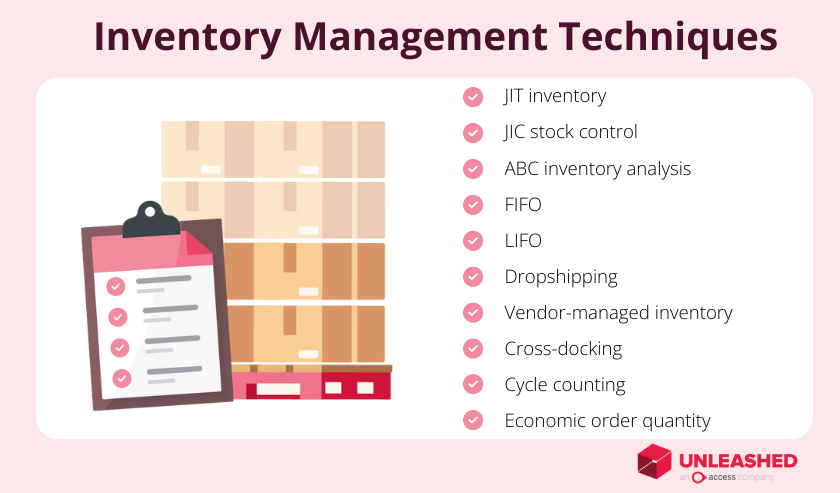

Effective inventory management techniques

Effective inventory management is crucial for businesses to optimize operations, reduce costs, and improve overall efficiency. Here are some of the most effective techniques for inventory management:

Demand forecasting

- Predicting future product demand is essential for adequate inventory levels to meet customer needs.

- Techniques for forecasting include moving averages, exponential smoothing, time series analysis, and judgmental forecasting. It’s crucial to note that demand forecasting is not exact, which may lead to stockouts or overstocks.

ABC analysis

- Prioritizes inventory items based on importance using ABC analysis.

- Categories include:

A Items: 20% of items but 80% of inventory value.

B Items: 30% of items and 15% of inventory value.

C Items: 50% of items but only 5% of inventory value.

Safety stock

- Extra inventory is kept to cover unexpected demand or delays in deliveries.

- Determined by demand variability, delivery lead time, cost of stockouts, and holding inventory costs

Reorder points

- Inventory levels trigger new orders, specific to each item.

- Based on average daily usage, order lead time, and safety stock to prevent stockouts.

PAR levels

- Periodic automatic replenishment (PAR) levels set minimum and maximum inventory limits.

- Helps avoid stockouts and overstocking, particularly suitable for businesses with perishable items.

Just-in-time (JIT) inventory

- Reduces inventory by ordering and delivering products precisely when needed.

- Requires close tracking of inventory levels and collaboration with suppliers.

Dropshipping

- No need to keep inventory in stock; products are shipped directly from third-party suppliers to customers.

- Popular for online businesses, but may result in lower margins and less control.

Cross-docking

- Receive inventory and ship products to customers without storing them.

- Reduces handling and holding costs, suitable for perishable products.

Inventory management software

- Software to track inventory levels, forecast demand, and place orders efficiently.

- Selection depends on business needs; enhances efficiency and reduces costs.

FIFO and LIFO

- FIFO sells the oldest inventory first, suitable for perishable goods.

- LIFO sells the newest inventory first, useful when inventory costs rise over time.

Consignment inventory

- The supplier retains ownership until goods are sold.

- The consignee covers holding costs and is responsible for selling; reducing upfront payment.

Economic order quantity (EOQ)

- Determines optimal order quantity to minimize total inventory costs.

- Considers annual demand, ordering cost, and holding cost.

Perpetual inventory management

- Continuously updates inventory levels as products are sold or received.

- Provides accurate inventory view, improves turnover, and avoids stockouts.

Minimum order quantity (MOQ)

- Sets the minimum inventory quantity ordered from a supplier.

- Reduces shipping costs for the supplier but may limit ordering flexibility.

Six Sigma and Lean Six Sigma

- Six Sigma reduces variations and defects in inventory management.

- Lean Six Sigma combines Six Sigma with lean manufacturing for increased efficiency.

Bulk shipping

- Purchasing and shipping inventory in large quantities to reduce costs.

- This can lead to overstocking, not ideal for perishable items.

Batch tracking

- Helps track groups of similar items in the supply chain.

- Commonly used for perishable and recallable inventory items.

Materials requirements planning (MRP)

- MRP is a comprehensive system designed to manage planning, scheduling, and inventory control within manufacturing processes.

Types of inventory control

There are two primary categories of inventory control methods: perpetual inventory and periodic inventory. Here’s a concise overview of each:

Perpetual inventory system

This system operates by continuously monitoring and managing inventory in real time. Whenever products are sold, their barcodes are scanned and promptly removed from the inventory database. Similarly, incoming products are scanned upon receipt and added to the database. This approach ensures immediate and precise information about current inventory levels.

Periodic inventory system

In this system, physical inventory counts are carried out at specified intervals, such as weekly, monthly, or annually. Inventory levels are then periodically updated based on these physical counts. Small businesses with fewer processes and a more limited inventory scope commonly employ this method.

Choosing the right omnichannel inventory management system for the retail industry

There are many types of omnichannel inventory management systems, and every one of these types has its advantages and disadvantages. The choice between them depends on each brand’s specific needs and characteristics.

Types of omnichannel inventory management systems

Cloud-based

- Hosted on remote servers accessible via the internet.

- Offers flexibility, scalability, and real-time updates.

- Enables seamless collaboration and access from multiple locations.

On-premises

- Installed and operated directly on a company’s in-house servers.

- Provides full control over the system but may require higher upfront costs.

- Suitable for businesses with specific security or customization needs.

Hybrid

- Combines features of both cloud-based and on-premises systems.

- Offers a balance between flexibility and control.

- Allows businesses to leverage cloud benefits while maintaining some on-site control.

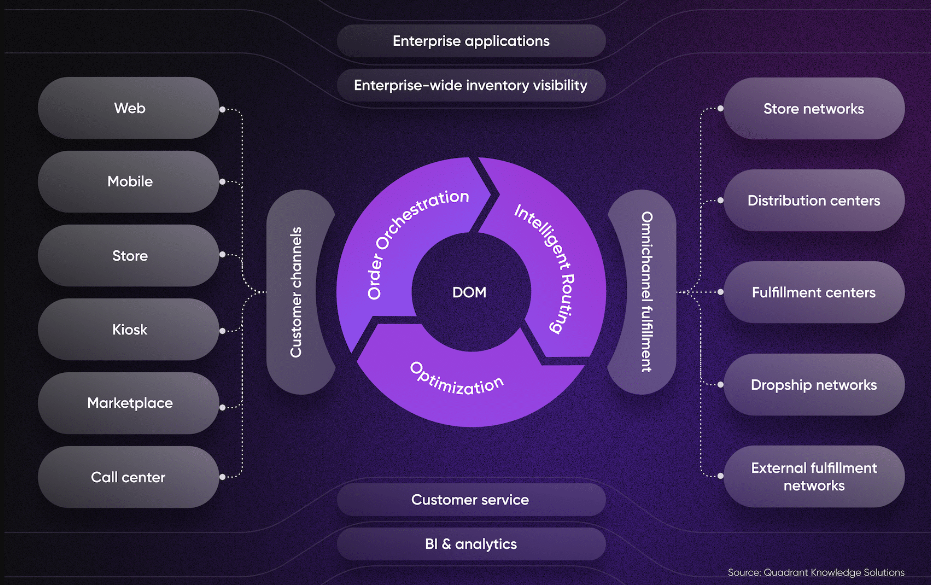

Distributed order management (DOM)

- Focuses on optimizing order fulfillment across various channels.

- Coordinates inventory, orders, and shipments efficiently.

- Enhances customer satisfaction by ensuring accurate and timely deliveries.

Real-time inventory

- Provides instant updates on inventory levels, orders, and product availability.

- Enables quick decision-making and reduces the risk of stockouts.

- Essential for businesses with dynamic and fluctuating demand.

Cross-channel integration

- Seamlessly integrates and synchronizes data across various sales channels.

- Ensures a consistent and unified customer experience.

- Enables efficient order processing and inventory management across channels.

Mobile inventory management

- Allows for inventory monitoring and control via mobile devices.

- Enhances flexibility and accessibility for on-the-go management.

- Particularly beneficial for businesses with mobile workforce requirements.

Machine learning

- Utilizes machine learning algorithms to analyze and predict inventory trends.

- Optimizes stock levels, reduces manual intervention, and enhances accuracy.

- Ideal for businesses dealing with large and complex inventory datasets.

RFID

- Utilizes Radio-Frequency Identification technology for tracking inventory items.

- Provides real-time visibility into inventory movements.

- Enhances accuracy in inventory management and order fulfillment.

Collaborative inventory management

- Facilitates collaboration between different stakeholders in the supply chain.

- Improves communication and visibility among suppliers, manufacturers, and retailers.

- Enhances overall supply chain efficiency and responsiveness.

Benefits of using omnichannel inventory management software

Adopting an omnichannel inventory management system can enable businesses to save time, cut costs, and elevate customer satisfaction by delivering a seamless and consistent experience across all sales channels.

- Enhanced customer satisfaction: Effectively overseeing inventory across various channels ensures product availability regardless of the shopping platform, contributing to heightened customer satisfaction.

- Elevated sales and profits: Omnichannel inventory management is effective for boosting sales and profits with the mitigation of out-of-stock instances, heightened fill rates, and diminished costs associated with inventory management.

- Real-time inventory visibility: An omnichannel inventory management system offers instantaneous insights into inventory levels across all channels, allowing businesses to make timely adjustments when necessary.

- Automation of tasks: These systems can automate tasks such as order fulfillment and shipping, resulting in decreased errors and enhanced operational efficiency.

- Optimized supply chain management: Managing inventory across diverse channels enables businesses to streamline their supply chain, effectively reducing costs linked to excess inventory and stockouts.

- Enhanced customer communication: Omnichannel inventory management facilitates tracking of the order status throughout its journey, enabling precise delivery times to be acknowledged to customers and fostering improved communication.

- Intelligent stock management: Through intelligent demand planning integrated with inventory levels, businesses can minimize wasteful dead stock, ensuring optimal inventory levels.

- Heightened productivity: Automation of processes liberates staff time, allowing them to redirect their focus to other tasks, consequently improving overall productivity.

Strategies and best practices for efficient omnichannel inventory management in retail

Effective inventory management is crucial for businesses to maintain profitability and customer satisfaction. If a retailer aims to gain a competitive edge in the realm of eCommerce businesses, it is imperative to have a clear understanding of your real-time inventory levels. This tactic involves comprehensive visibility into inventory across all channels, encompassing brick-and-mortar stores, eCommerce sites, and various marketplaces. Achieving this level of insight necessitates the need for a technology solution offering real-time inventory tracking.

Encouraging in-store returns

Facilitating in-store returns can significantly benefit overall profit margins. Encouraging customers to return items in-store presents several advantages:

- In-store purchases: Customers returning items may find alternative products during their in-store visit, contributing to additional sales.

- Time-saving: In-store returns eliminate the need for customers to print return shipping labels and visit shipment businesses, saving time and enhancing customer satisfaction.

Moreover, even if a customer opts not to make an additional purchase during an in-store return, businesses can still gain the opportunity to sell the returned item in-store without incurring the costs associated with warehouse handling and online relisting.

Integrating the supply chain

Integration of the supply chain provides end-to-end visibility, tracking the stops a product makes from the point of order to its arrival at a customer’s doorstep or in-store. This type of heightened visibility facilitates tracking products in real time, allowing businesses to proactively address potential issues. Furthermore, supply chain integration offers insights into inventory levels, enabling timely adjustments to prevent stockouts, a critical consideration during peak demand periods like holidays.

Optimizing return policies

Enhancing return policies is a crucial aspect of omnichannel inventory management. Clear, concise, and flexible return policies contribute to improved customer satisfaction and operational efficiency. Considerations include:

- Policy clarity: Ensure that your return policy is transparent, easily comprehensible, and adaptable based on product, channel, and customer.

- Varied options: Offer diverse return options such as store credit, exchanges, or refunds, tailored to different products and customer preferences.

Communicating these policies clearly to customers fosters transparency and manages expectations. While processing returns incurs costs, a well-structured return policy encourages repeat business and enhances the overall customer experience.

Building a customer satisfaction plan

Establishing a robust customer satisfaction plan involves creating systems for tracking and responding to customer complaints or queries. This proactive approach demonstrates a commitment to customer experience and a willingness to address issues promptly. Elements of a comprehensive customer satisfaction plan include:

- Tracking mechanism: Implement a system for efficiently tracking customer complaints or queries.

- Handling returns and exchanges: Establish a clear process for handling returns and exchanges, ensuring a smooth and customer-friendly experience.

- Feedback response: Develop a process for responding to customer feedback, showing a commitment to continuous improvement.

By prioritizing customer satisfaction, businesses can cultivate loyalty, encourage repeat customers, and benefit from positive word-of-mouth marketing.

Stocking inventory across multiple locations

The evolution of online retail has necessitated a shift from centralizing inventory in a single location to dispersing it across multiple points. This approach offers several advantages:

- Proximity to customers: Distributing inventory across various locations brings products closer to the customer base, contributing to faster shipping times.

- Resilience to issues: Multiple locations provide a contingency plan in case of issues, such as weather-related problems in one warehouse.

- Perishable items management: For businesses dealing with perishable items, having inventory spread across locations allows for a flexible response. In case one location faces stockouts, products can quickly be sourced from another to maintain customer satisfaction.

Centralized inventory management

Centralizing inventory management involves tracking inventory levels in real time across all channels. This approach ensures accuracy and up-to-date information, facilitating optimization of inventory levels and mitigating stockouts. The advantages of centralized inventory management include:

- Unified approach: Businesses can maintain a consistent and unified approach to inventory management across various sales channels.

- Preventing stockouts: Real-time tracking helps prevent stockouts, ensuring products are available when customers demand them.

Cloud-based inventory management system

Adopting a cloud-based inventory management system allows businesses to access inventory data from anywhere. This accessibility is crucial for managing inventory across multiple locations and channels. Cloud-based systems offer scalability and flexibility, making them ideal for businesses experiencing rapid growth.

Real-time inventory tracking

Real-time inventory tracking enables businesses to monitor inventory levels instantaneously across all channels. This capability aids in optimizing inventory levels, preventing stockouts, and ultimately enhancing sales and customer satisfaction.

Optimizing inventory levels

Optimizing inventory levels involves leveraging sales data and demand forecasting to prevent overstocking or understocking. By strategically adjusting stock levels, businesses can reduce costs and improve operational efficiency.

Automation

Automation enhances operational efficiency by automating processes such as order fulfillment and inventory tracking. This results in improved accuracy and faster order fulfillment, contributing to overall customer satisfaction.

Challenges and solutions in inventory management

While the benefits of adopting an omnichannel strategy outweigh the challenges, it’s imperative to address these challenges effectively.

- Segmented supply chain processes: Omnichannel requires connectivity, which is hindered by segmented supply chain processes. Siloed supply chains create gaps leading to issues like incorrect advertising of out-of-stock items and delivery delays.

- Lack of inventory visibility: Inventory visibility relies on accurate data which can be a significant barrier to implementing an omnichannel inventory management strategy. Impacts scaling and expanding into new channels as bad data adversely affects these processes.

- Order accuracy: Accurate inventory display is critical for establishing customer trust as it facilitates faster dock-to-stock cycles and ensures customers receive the desired product within the expected timeframe. Difficult to implement an omnichannel inventory management system without reliable data.

- Order tracking: Modern online shopping has raised customer expectations for real-time order tracking. The inclusion of order tracking as part of the fulfillment process is now a requirement. An essential consideration when integrating a new platform.

- High inventory storage costs: Omnichannel inventory management requires smart inventory management to avoid wasteful dead stock and minimize storage costs. Smart demand planning to feed into inventory levels helps prevent unnecessary costs and ensures margins meet expectations.

- Technology: An inventory or warehouse management system is the backbone of an omnichannel approach. Manual processes are not feasible for omnichannel operations. Automated technology solutions streamline every process, synchronizing order fulfillment across channels simultaneously and providing robust reports for informed stocking decisions.

Implementing inventory management for scaling retailers

Effective inventory management is crucial for the success of retailers and small businesses. While large-scale businesses may invest in expensive software solutions, there are several cost-effective strategies and practices that smaller enterprises can implement. Here are some tips for scaling retailers and small businesses:

- Regular audits and tracking: Implement a regular schedule for manual inventory audits to ensure accuracy. Track inventory movements consistently, updating records whenever stock is received or sold.

- Set par levels: Determine optimal stock levels for each product to avoid overstocking or understocking. Adjust par levels based on historical sales data and market trends.

- Vendor relationships: Develop strong relationships with suppliers to negotiate favorable terms, such as bulk discounts or flexible payment terms. Communicate effectively with suppliers to anticipate delivery times and potential delays.

- Forecasting: Use historical sales data to forecast future demand. Adjust your inventory levels based on seasonal trends and market fluctuations.

- Excel spreadsheets: Utilize spreadsheet software like Microsoft Excel or Google Sheets to create a simple inventory tracking system. Maintain organized sheets with information on stock levels, reorder points, and sales data.

- Barcode scanning apps: Explore cost-effective barcode scanning apps that can be used with smartphones or tablets. These apps can help streamline the tracking process and reduce errors associated with manual data entry.

- Prioritize fast-moving items: Focus on efficient management of fast-moving items to minimize storage costs and improve cash flow. Consider implementing just-in-time inventory practices for items with high turnover.

- Utilize free or open-source software: Explore free or open-source inventory management software options that may offer basic features without the cost of premium solutions. Look for platforms that are scalable so you can upgrade as your business grows.

- Cloud-based solutions: Consider cloud-based inventory management solutions, which often have more affordable subscription models than traditional software. Cloud-based solutions provide accessibility and real-time updates without the need for expensive infrastructure.

- Consignment inventory: Consignment inventory is a business arrangement where a supplier (consignor) provides goods to a retailer or reseller (consignee) without transferring ownership until the goods are sold. This model offers several benefits for rising businesses, helping them manage inventory costs and respond to increasing business needs more efficiently.

Omnichannel inventory management FAQs

Q: What is omnichannel inventory management?

A: Omnichannel inventory management is the process of strategically managing inventory across multiple sales channels, such as brick-and-mortar stores, e-commerce platforms, and mobile apps, to ensure seamless retail operations.

Q: What are the best inventory management strategies for seamless retail operations?

A: Some of the best inventory management strategies include leveraging technology to track inventory levels in real time, implementing a robust order management system, and integrating warehouse management for efficient fulfillment.

Q: How can cloud-based inventory management solutions benefit retail operations?

A: Cloud-based inventory management solutions offer accessibility, scalability, and real-time insights, enabling retailers to manage their inventory across multiple channels and locations with ease and efficiency.

Q: What are some examples of effective inventory management software for retail businesses?

A: Some examples of effective inventory management software for retail businesses include systems that offer features such as demand forecasting, automated inventory replenishment, and integration with point-of-sale systems.

Q: How does manufacturing inventory management contribute to seamless retail operations?

A: Manufacturing inventory management ensures that the right amount of raw materials and finished goods are available to support retail operations, minimizing stockouts and overstock situations.

Q: What are the key methods for managing inventory effectively in a retail setting?

A: Key methods for managing inventory effectively in a retail setting include implementing a perpetual inventory system, optimizing order fulfillment processes, and conducting regular physical inventory counts.

Q: How can proper inventory management help retailers control inventory costs?

A: Proper inventory management can help retailers control inventory costs by minimizing excess inventory, preventing stockouts, and optimizing replenishment cycles based on demand patterns.

Q: What are the essential inventory management tools for seamless retail operations?

A: Essential inventory management tools for seamless retail operations include barcode scanners, inventory management software, RFID systems, and automated inventory tracking systems.

Q: How can retailers ensure consistency in inventory across different sales channels?

A: Retailers can ensure consistency in inventory across different sales channels by implementing integrated inventory management systems that synchronize inventory data in real time and enable centralized control.

Q: What is the goal of inventory management in the retail industry?

A: The goal of inventory management in the retail industry is to achieve optimal inventory levels, minimize stockouts and overstock situations, improve order fulfillment efficiency, and enhance overall customer satisfaction.

Q: What is the difference between supply chain management and inventory management?

A: Supply chain management and inventory management are both crucial components of a business’s operations but they focus on different areas:

Supply Chain Management (SCM) encompasses the entire process of producing and delivering a product or service, from the raw material stage to the end consumer. It includes managing relationships with suppliers, coordinating production processes, ensuring efficient transportation and logistics, and maintaining customer satisfaction. SCM aims to optimize the entire chain to reduce costs and improve efficiency and customer service.

Inventory Management, on the other hand, is a subset of supply chain management. It specifically focuses on the tracking and control of goods and materials that a business holds in stock. The primary goal is to ensure that there is always enough inventory to meet customer demand without overstocking, which can lead to increased costs. Inventory management involves tasks like forecasting demand, setting inventory levels, reordering points, and managing storage space.

Insightful resources to achieve 360-degree Omnichannel Retail

- Omnichannel Retail: All You Need to Know for 2024

- 28 Brilliant Omnichannel Marketing Examples by Famous Retailers

- What Is a Customer Data Platform, and Why Does a Retailer Need One

- The Omnichannel Chatbot Revolution: 18 Key Benefits for Any eCommerce Business

5 reasons why ContactPigeon works brilliantly with any retail inventory management system

- ContactPigeon is built especially for retailers, being one of the few platforms offering omnichannel capabilities for physical stores as well.

- It supports a lot of different channels for omnichannel reach: Email, Push Notifications, SMS, Viber, WhatsApp, Chat, and so on.

- Numerous world-class brands like L’Oreal, Hertz & Gap have trusted ContactPigeon so far.

- It is among the 5 top-rated omnichannel customer engagement platforms in Europe, according to G2.

- Its top-tier customer support offers an assigned omnichannel expert per client for monthly sessions and will guarantee seamless integration to any CMS and enterprise software.

You can book a DEMO here to learn more!

Let’s Help You Scale Up